METSERVICE Łukasz Szałas ul. Wielkopolska 3G 26-600 Radom

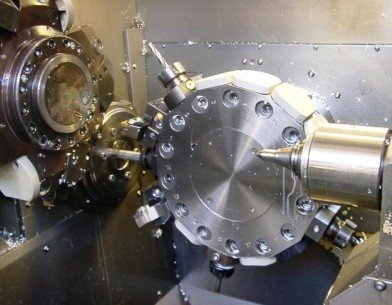

Machines

Citizen series L

– Mitsubishi Meldas steering

– maximum diameter of the processed material: 32 mm

– machine equipped with a counter spindle

– tools driven for the main spindle

– 5 machining axis

– bar feeder with a FMB depot of 3 meters

Machines used for production of the long details L>3xØ for ensurance of the best quality of workmanship.

Dugard Eagle 32 SUB

– Syntez 900 steering

– maximum diameter of the processed material: 32 mm

– machine equipped with a counter spindle

– tools driven for the main spindle and for the counter spindle

– 7 machining axis

– bar feeder with Fedek 532 depot

Machines used for production of the short details L<3xØ with high level of complexity, with multi-axis machining, also using milling or cross drilling.

Index series GE

– Sinumerik steering

– maximum diameter of the processed material: 42 mm

– possibility of installing the detail interception

– machine equipped with driven tools

– MBF bar feeder

Machines used both for roughing and finish machining. Machines with high spindle and machining axis power. Possibility of bar machining as well as work in a lathe chuck.

CHIRON series FW

– Sinumerik steering

– three-axis machine tool

– machine equipped with a rotating pallet table

– X-Y-Z 550x300x280

– maximum spindle speed 10 000 min-1

Machine used for machining mainly aluminum elements or steel elements (light machining). Machine tool designed for high-volume manufacturing.

Screw machines MAS A20B

– cam-controlled machines used for machining simple elements

– automats used only for large-scale machining

– maximum spindle bore 22 mm

Additional devices

– thread rolling mills – making threads in the range of 5-20 mm

– machines for making internal threads in the range of 3-16 mm

Welding equipment MIG, TIG

– black steel and aluminum welding using rotating tables and welding automats